CAE software creates uniform global standard

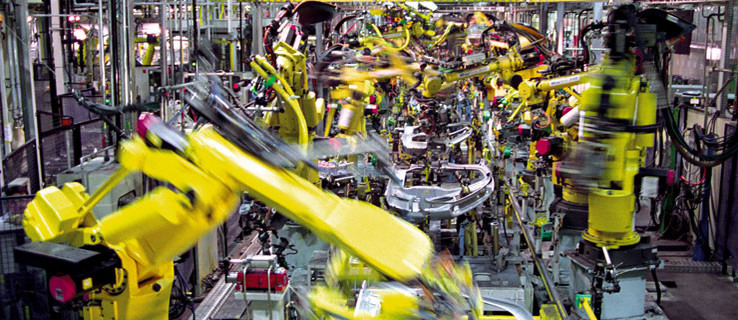

When a car manufacturer like General Motors chooses a CAE tool, its decision is based on careful consideration.

When a car manufacturer like General Motors chooses a CAE tool, its decision is based on careful consideration. In this particular case, the main aims were to establish a uniform global standard for all plants, facilitate inter-site engineering, and support both object-oriented and drawing-oriented working methods.

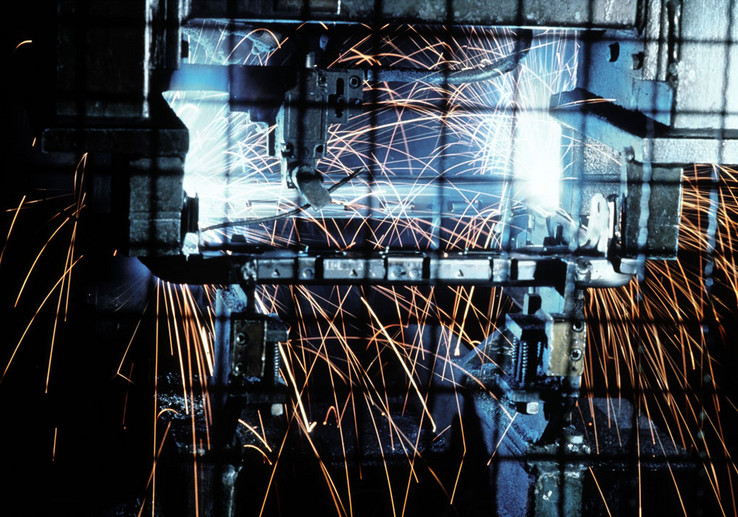

With the automated transfer of standards, the program should even be able to refresh old projects at a click of the mouse. Beta testers are critical people, who are often hard to convince. Daniel King is a Principal Engineer and beta tester for the software EPLAN Electric P8 in Detroit, Michigan. In 2005, King began working at GM to test the E-CAE program’s suitability for the world’s largest automobile manufacturer.

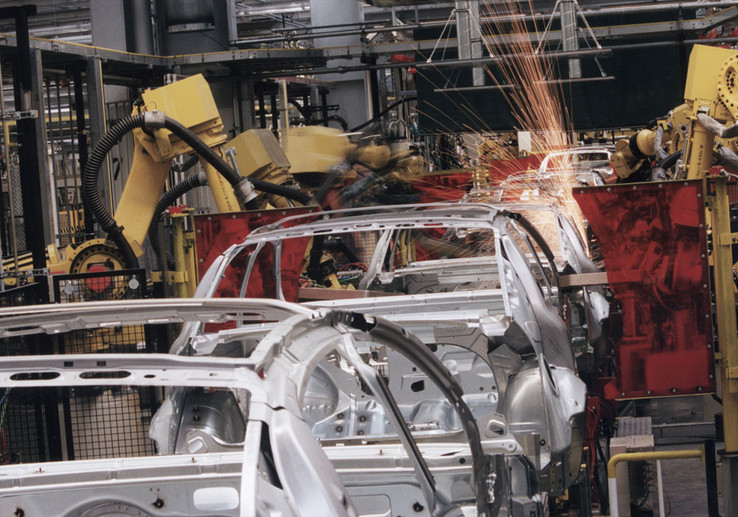

By April 2006, at the Hanover Trade Fair, the usually taciturn engineer was to be found in Hall 15, enthusiastically summing up his impressions of this latest dimension in CAE. His succinct summary: “At last, we have the opportunity to bring many different engineering tools together on a worldwide basis”. Many of GM’s specific requirements were incorporated directly into the software development process. “Going Common & Global” is the motto of these giants of the automotive sector, who are currently in the process of replacing the predecessor versions, EPLAN 5 and EPLAN 21, with this new CAE system. Global engineering poses major obstacles for large corporations wishing to unify their electrical engineering documentation. European countries follow different standards than the USA or Asia, for example. As a result, global projects often need to be updated to new languages, output formats and standards – a time-consuming task for the designers. The problem at General Motors is that the company has used EPLAN 21 as its object-oriented system since 2002, while its subsidiaries Opel, Saab and Vauxhall and their suppliers have been using EPLAN 5, a graphically oriented CAE tool, since the Nineties.

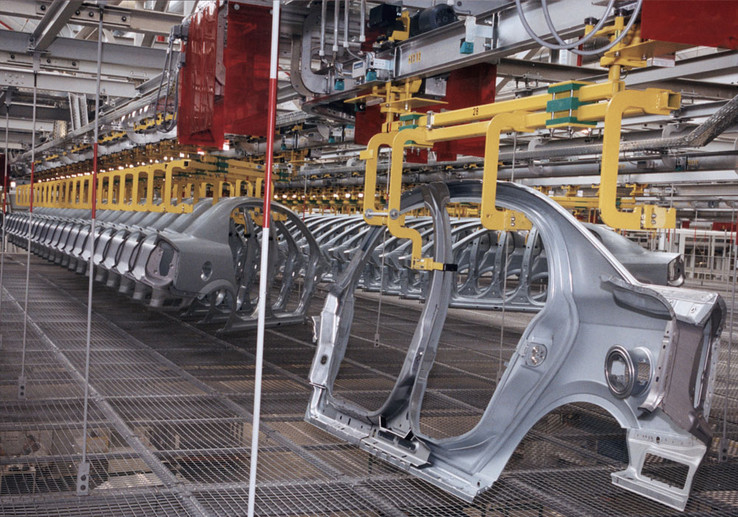

Until now, the US auto firm has had to live with this split – but all that is about to change. The new EPLAN P8 system supports both graphically oriented and object-oriented working methods equally. “Clients no longer need to weigh up the pros and cons of these two approaches”, stresses Thomas Michels, Product Manager at EPLAN. The program intuitively guides the designer to the most suitable operating concept for each given task. A user who starts off with a graphically oriented approach can easily and smoothly switch to an object-oriented method later on. Thomas Michels explains the benefits: “If the design department already has the know-how, it is simply transferred. A two-part data model helps to ensure that implementation is successful.” The automatic transfer of standards is particularly appreciated by global players like GM, because it is vital to comply with the valid standards for each country. In the case of global production at GM, this means that the program supports all international standards such as IEC 61346, JIC, NFPA or the Russian GOST. But that is not all – completed projects are automatically converted into the required local standard. The standard templates, evaluation forms and mapping of the different symbol libraries may be defined, and the system even automatically converts old projects into the chosen standard. Just one click, and the projects can be e-mailed anywhere in the world via PDF export.

When a company makes the decision to switch to a new software, it wants to be able to get started straight away. This is possible with P8. Not only does the interface support flexible adaptation; various tasks and work phases may also be configured and stored, then re-accessed by the designer as and when needed. This offers a clear benefit for General Motors, where both predecessor systems – EPLAN 5 and 21 – were previously used by the various subsidiaries. If PLC editing is the main focus of project planning, the views and editing dialogs may be adapted to bus and PLC data. For each editing stage, the relevant information is immediately accessible. Although designers will get to grips with the program immediately, training courses can help them to gain maximum benefits from it.

EPLAN Software & Service has produced a special training manual to help GM employees and suppliers to work profitably with the software while observing uniform GM standards. Worldwide support is invaluable, and Daniel King appreciates the high level of service provided: “I cannot imagine achieving these major global targets without the support of EPLAN as our powerful partners”.